■ Product

| Design & Manufacturing |

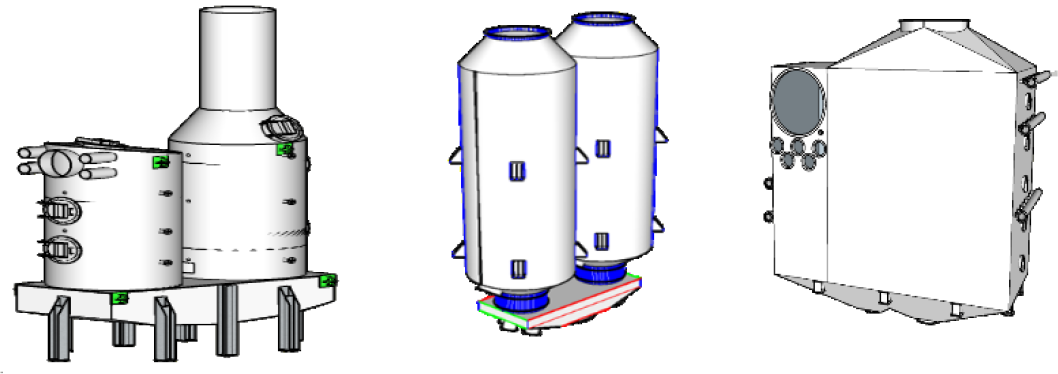

Sox Scrubber | NOx & Sox Manufacturing |

| Type in Shape | U-type / I-type | |

| System in Loop | Open / Closed / Hybrid | |

JW ENC Co., Ltd.

■ Reference Dimension & Weight

| U-type | ||||||||||

| Design Capacity(MW) | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 |

| DxBxH (m)) | 3.1x6.0x9.0 | 3.7x7.0x9.0 | 4.2x7.85x9.6 | 4.7x8.75x9.6 | 5.1x9.45x9.6 | 5.5x10.2x9.6 | 5.6x10.03x10.5 | 6.3x11.6x10.5 | 6.9x12.6x10.5 | 7.5x13.65x10.5 |

| Weight(Ton,Dry) | 1.51 | 19.2 | 23 | 26.5 | 29.6 | 34.2 | 35.5 | 42.3 | 48.5 | 54.5 |

| I-type | ||||||||||

| Design Capacity(MW) | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 |

| DxBxH (m)) | 3.1x11.9 | 3.7x11.9 | 4.2x13.6 | 4.7x13.6 | 5.1x13.6 | 5.5x13.6 | 5.6x14.6 | 6.3x14.6 | 6.9x14.6 | 7.5x14.6 |

| Weight(Ton,Dry) | 12.1 | 14.5 | 17.9 | 20.1 | 22.4 | 24.3 | 25.2 | 30.3 | 33.5 | 36.9 |

■ SOx Abatement Scrubber : Two Diffrent Extraordinary Technology

| ExhClean | Advantages | Other Makers |

| Using urbulant Vortexdevice |

✓ Long Uniform Gas Path ✓Low Pressure Drop ✓ No Replacement Parts |

Using Packed Bed Technology Non-uniform Gas Flow ✓ Higher Pressure Drop ✓ Regular Replacement |

| Using Multi Semi-venturi |

✓ No Back Flow of Exh. Gass ✓ No Interference |

✓ Using Single Nozzle(or Venturi) ✓Po ble to be Back flow ✓Interference between gas |

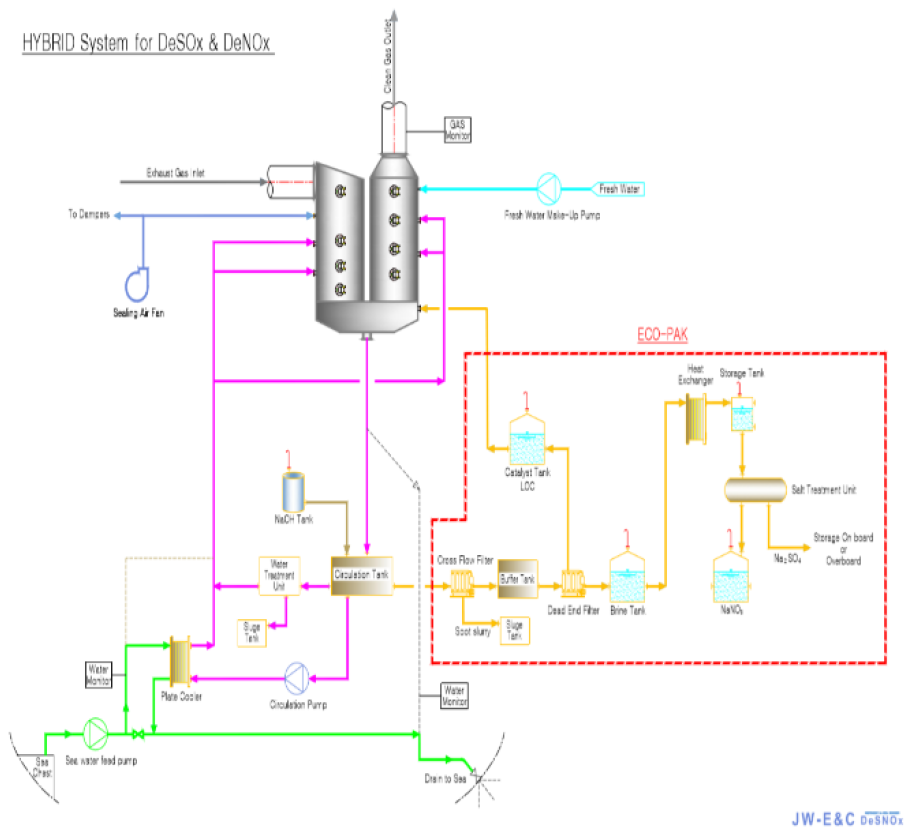

■ NOx & SOx Abatement Scrubber : Only one Technology in the World Technical Comparison

| Description | ExhClean De-SOx/NOx | Other Scrubber + SCR sys. |

| CAPEX & OPEX | Lower | High |

| Footprint | Less than Typical system | More than ExhClean |

| Maintenance & Installation | No Down time of M/E & Simple | Down time for catalyst replacement & Complex |

| Operation Condition | Regardless of •Exh. Gas temp.

• content in F.O |

Restriction, 320 °C & above required

• High S content to be affected to SCR |

| Impact on Engine performance |

No Influence on • SFOC

•Exh. Gas back Pressure |

Absolute influence |

| Apply to Tier Ⅱ engines | Applies without problem | Not applicable |